acuthread

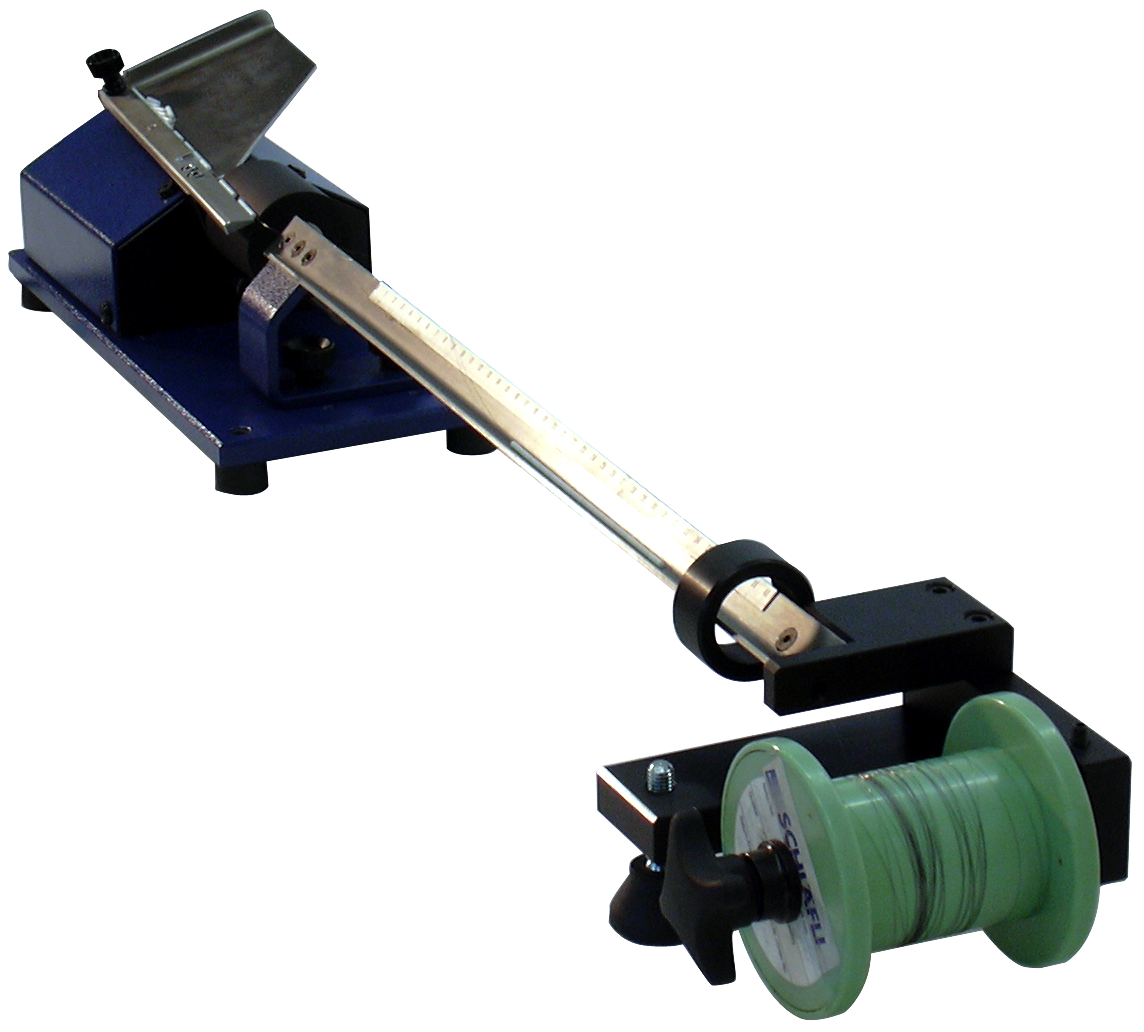

All work pieces need to be threaded on a wire in order to machine them on the wire honing machines and the wire guided centerless grinding machine acugrind-C. The smaller the parts inner diameter the harder and more time-consuming is this operation. Using the specially designed acuthread the process is simplified and accelerated considerably.

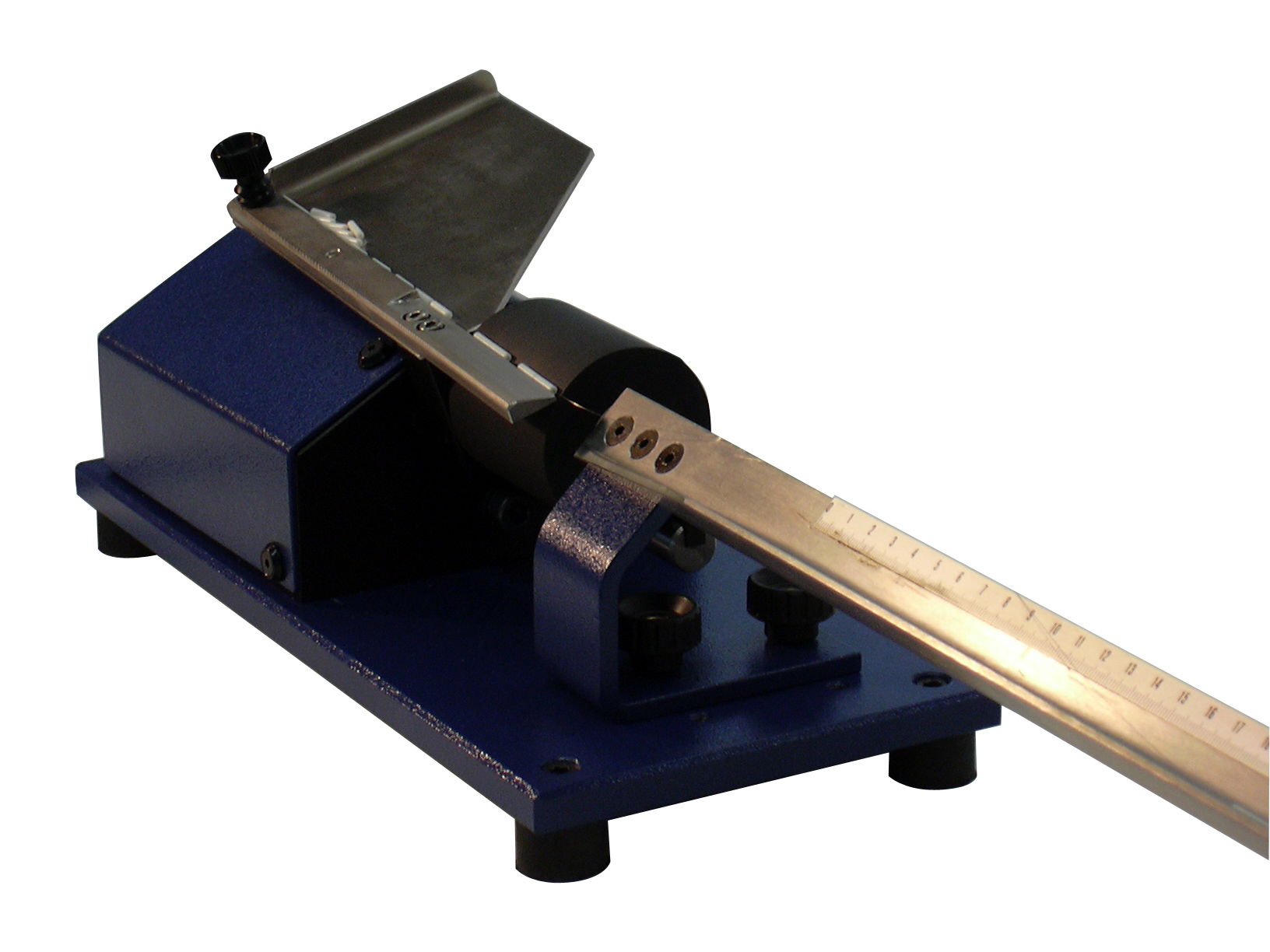

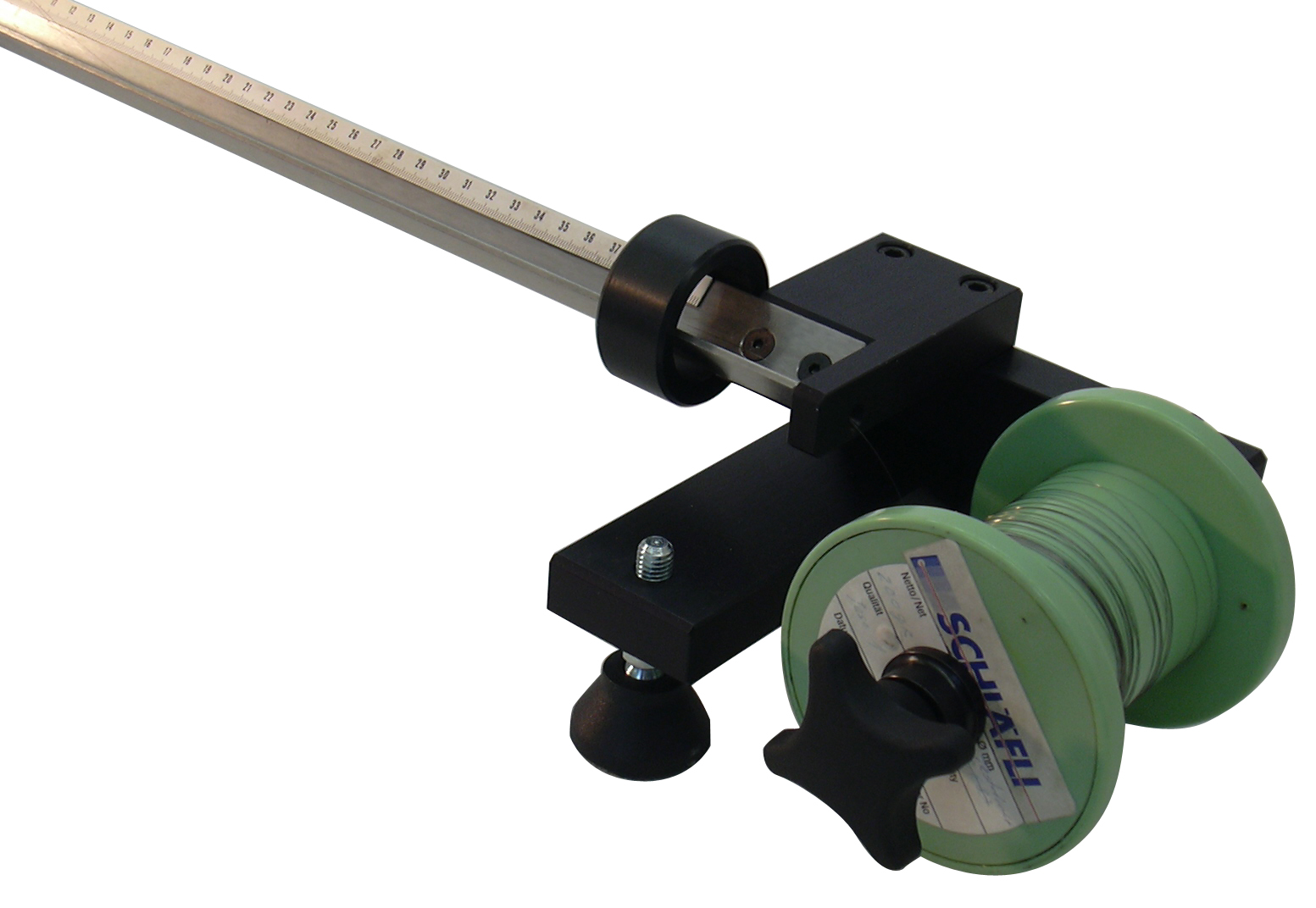

The cleaned parts are placed on a guiding plate and glide to a rotating rubber roll. The roll moves the parts slowly towards the wire where the parts are threaded manually onto the wire. The threading is facilitated due to the guidance and the rotation of the parts.

The automatic threading system acuthread is light and can be placed on to any even and stable surface.

Dimensions (length x width x depth)

• 160 x 16 x 14 cm for the centerless grinding machine acugrind-C

• 92 x 16 x 14 cm for all wire honing machines